McBurney’s engineers are dedicated to providing engineering and consulting services to the steam and power industry. Over the years, the engineering effort has expanded to cover a wide range of special projects, with steam and power engineering remaining the firm’s primary focus.

McBurney’s engineers are dedicated to providing engineering and consulting services to the steam and power industry. Over the years, the engineering effort has expanded to cover a wide range of special projects, with steam and power engineering remaining the firm’s primary focus.

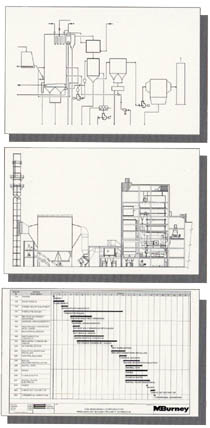

McBurney has gained experience on a wide range of steam and power plant projects. The majority of these projects has been waste fuel fired (e.g. wood waste, bagasse, peanut hulls, NRP, MSW, RDF, sludge, rice hulls, coconut husks, plastics, and landfill gas) which enables us to understand the special requirements of fuel handling, ash handling, and environmental control. McBurney also has extensive experience with conventional boiler design and fuels including natural gas, fuel oil, and coal.

We have established a highly motivated, experienced, and multi-disciplined engineering staff specializing in mechanical, civil, structural, piping, electrical, estimating, process instrumentation, and control disciplines.

Our engineers utilize advanced engineering and management tools to create plants that provide high efficiency and availability. Each project phase is carefully planned to develop the best approach from detailed scheduling and cost control, to carefully monitored material purchasing and expediting methods, to detailed construction and testing procedures.

Our engineering staff, through interaction with our construction organization, understands the significance of value engineering and the importance of including construction and maintenance considerations as part of the design.

Providing energy and environmental engineering solutions worldwide, the McBurney design team is ready to utilize its experience to make your project a success.

Engineering Services Include:

Project Management

Project Management- Project Scheduling

- Feasibility Studies

- Project Development Engineering

- Power Plant Design

- Environmental Permit Support

- Estimating

- EPC / Design – Build / Detailed Design

- Performance Engineering

- Heat and Material Balances

- Power Plant Optimization

- Plant Renovation

- Control System Upgrades

- Operation Manuals and Operator Training

- Equipment and Material Specifications

- Equipment and Material Procurement

- Start-Up Assistance

- Troubleshooting

- Condition Assessment

- Inspection Services